The “Zero Bounce” Advantage of Mercury Wetted Relays

Why Mercury Wetted Relays remain the gold standard for high-speed pulse generation and high-power switching.

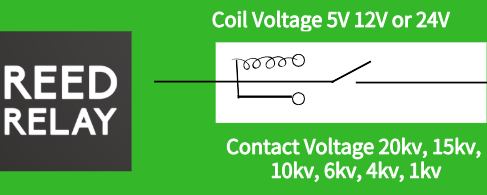

While dry reed relays are excellent for general purpose switching, they suffer from a phenomenon known as Contact Bounce. When mechanical contacts close, they physically bounce apart for microseconds before settling. For high-speed instrumentation or high-power loads, this bounce can cause data errors or contact welding.

How Mercury Technology Works

In a Mercury Wetted Relay (such as our HGMR or HVR Series), a thin film of mercury covers the contact surfaces. By capillary action, this mercury reservoir is constantly replenished.

When the contacts close, the liquid mercury bridges the gap instantly. There is no solid-to-solid impact bounce. The connection is immediate, clean, and stable.

Key Benefits

- Zero Contact Bounce: Essential for pulse counters and high-speed logic circuits where a “bounce” could be read as a double-signal.

- Self-Healing Contacts: Every time the relay opens, the mercury film breaks cleanly. If any slight pitting occurs, the liquid mercury flows back to “heal” the surface. This extends life expectancy to billions of operations.

- Stable Contact Resistance: The liquid connection ensures consistently low resistance throughout the life of the component.

- High Power Capability: The mercury film helps dissipate heat and prevents welding, allowing compact relays like the HGSR Series to switch up to 100W/5A.

Important Usage Considerations

MiRelay Mercury Solutions

We offer a comprehensive range of mercury wetted options:

| Series | Type | Best For |

|---|---|---|

| HGMR | Miniature DIP | General purpose, long life. |

| HGJR | Surface Mount (J-Lead) | Automated assembly, compact design. |

| HGSR | Industrial High Power | Heavy loads (8.5A Carry), Multi-pole. |

| HVR/MH | High Voltage | High voltage testing (up to 5000V). |