Product Selection Guide

From signal switching to high-voltage disconnects. A comprehensive guide to choosing the right MiRelay technology for your application.

Reed Relay vs. EMR vs. SSR

Why choose a Reed Relay? Understand the fundamental differences.

| Feature | Reed Relay | EMR (Armature) | Solid State (SSR) |

|---|---|---|---|

| Switching Speed | Fast (0.5 – 1ms) | Slow (10 – 20ms) | Instant (< 0.1ms) |

| Contact Resistance | Very Low (< 150mΩ) | Low (< 100mΩ) | High (Voltage Drop) |

| Isolation | Excellent (>10¹² Ω) | Good | Fair (Leakage Current) |

| Signal Integrity | Excellent (Linear) | Good | Poor (Distortion) |

| Life Expectancy | High (10⁹ Ops) | Medium (10⁶ Ops) | Infinite |

Understanding Contact Forms

Normally Open. The most common type. Contact closes when coil is energized. High isolation.

Normally Closed. Contact opens when coil is energized. Used for fail-safe circuits.

Changeover. Switches one common line between a Normally Open and Normally Closed path.

Switching vs. Carry Current

This distinction is the #1 cause of relay selection errors.

Switching Current

The maximum current allowed at the moment the contacts open or close. This is limited by arcing, which damages the contact surface.

- Dry Reed: Typically 0.5A – 1.0A

- Mercury Wetted: Typically 2.0A – 5.0A

Carry Current

The maximum current allowed to flow through already closed contacts. This is limited by heating (I²R losses).

- Dry Reed: Typically 1.0A – 2.5A

- Mercury Wetted: Typically 5.0A – 10.0A

Example: A 10W relay switching 200V is limited to 0.05A (P = V * I).

MiRelay Series Comparison

| Series | Type | Max Voltage | Max Carry | Key Feature | Typical Application |

|---|---|---|---|---|---|

| SIP | Dry Reed | 200V | 1.5A | Standard Size | General ATE, Industrial |

| MSIP | Dry Reed | 200V | 1.0A | Miniature | High Density Matrix |

| HVR | Dry Reed | 5000V | 3.0A | High Voltage | Cable Testers, Hipot |

| HGMR | Mercury | 1000V | 2.0A | Zero Bounce | Precise Instrumentation |

| HGSR | Mercury | 2500V | 5.0A | High Power | Pulse Generators |

How to Read Part Numbers

SIP

MSIP

HGMR

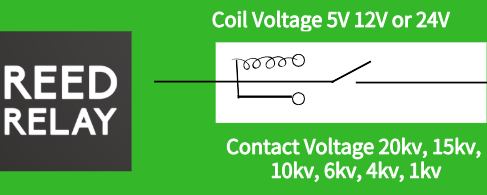

05 = 5V

12 = 12V

24 = 24V

1A = 1 Form A

1C = 1 Form C

2A = 2 Form A

D = Diode

S = Shield

H = High Volt

Need a Recommendation?

Our engineers can review your circuit requirements and suggest the exact part.