Relays for Third Generation Semiconductor Testing Equipment

With the development of 5G, new energy vehicles, charging stations, photovoltaics, and rail transit, the demand for semiconductor devices is growing, and the requirements for their reliability and performance are becoming increasingly stringent. Thus, the third-generation semiconductor market has emerged.

Third-generation semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) require high voltage and large current testing, which demands relays with high switching voltage and withstand voltage and high current pulse endurance. Micronale Electronics provides a series of relays using internationally matured mercury and dry reed technologies, which, through rigorous internal screening tests, can meet the requirements of third-generation semiconductor testing equipment:

- High insulation resistance High insulation has always been the pursuit of semiconductor testing equipment. Leakage current between high and low voltages must be less than 0.1nA under 1000V voltage, which requires the relay’s insulation resistance to be above 10T ohms. Micronale Electronics’ HGFR series mercury relays and HVFG series dry reed relays use special processes to ensure that the insulation resistance between contacts, between contacts and coils, fully meets customer needs.

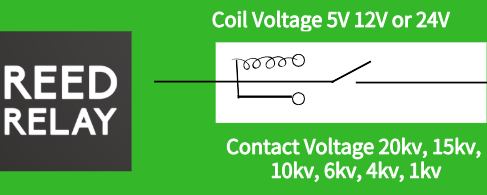

- High withstand voltage As the first choice for testing third-generation semiconductor devices, Micronale relays have high insulation and withstand voltage characteristics, with the highest withstand voltage of the dry reed relay reaching 20KV and that of the mercury dry reed relay exceeding 10KV.

- Long switching life Semiconductor packaging testing factories operate 24 hours a day, and have high requirements for the switching efficiency of relays. Micronale’s dry reed relays have a switching time of less than 1.2ms, and can achieve several hundred switching times per second, easily meeting customers’ efficiency requirements. At the same time, the contact coating uses rare metal ruthenium materials to ensure the stability of contact resistance after billions of switching times, meeting the requirements of high switching life.

I. Mercury Dry Reed Relays

- 8KV high-voltage mercury dry reed relay MH series

- High-power mercury relay with a withstand voltage of up to 10KVDC

- High load current capacity with a switching current of up to 5A

- Contact resistance, long-life sealed contacts

- Insulation resistance above 1T

- 4KV high-voltage mercury dry reed relay HGSR series

- Contact forms: 1A/1C/2A/2C

- High-power mercury relay with a withstand voltage of up to 4.5KVDC

- High load current capacity: conductive current of up to 8.5A, pulse current of 100A

- Low contact resistance, long-life sealed contacts

- Insulation resistance above 10T

- High-insulation mercury dry reed relay HGFR series

- Contact forms: 1A/2A/3A/4A

- High-power mercury relay with a withstand voltage of up to 3.5KVDC

- High load current capacity, conductive current of up to 3A

- Low contact resistance, long-life sealed contacts

- Insulation resistance above 10T

- Small-size mercury dry reed relay HGMR series

- Multiple pin arrangements to choose from

- High-power mercury relay with a withstand voltage of up to 2KVDC

- High load current capacity, conductive current of up to 3A

- Low contact resistance, long-life sealed contacts

- Insulation resistance above 1T

II. High voltage Dry Reed Relays

Migueli Electronics also offers a series of high-voltage dry reed relays, including the HVRD and HVD series. These relays have the following features:

High insulation resistance: The insulation resistance of these relays is above 10^12 ohms, which ensures reliable performance in high-voltage applications.

High voltage withstand capability: The HVRD series dry reed relays can withstand up to 10KVDC, while the HVD series can withstand up to 15KVDC.

Long switching life: The dry reed contacts have a long life of up to 10^10 cycles, ensuring reliable performance over a long period of time.

Low contact resistance: The contact resistance is typically below 50 milliohms, which ensures low power consumption and low heat generation.

High-speed switching: The HVRD series dry reed relays have a switching time of less than 100 microseconds, which makes them suitable for high-speed switching applications.

III. Conclusion

In summary, Migueli Electronics offers a range of high-quality relay products that meet the requirements of third-generation semiconductor testing equipment. The company’s HGFR series mercury relays and HVFG series dry reed relays have high insulation resistance, high voltage withstand capability, and long switching life, making them ideal for high-voltage, high-current testing applications. The company’s HVRD and HVD series dry reed relays offer similar capabilities in a compact and reliable package. With these products, Migueli Electronics is well-positioned to serve the growing demand for third-generation semiconductor testing equipment.