HM05-1A83-150 Reed Relay

The Unsung Hero of High Voltage: A Deep Dive into the HM05-1A83-150 Reed Relay

In the intricate world of electronics, some components are generalists, found everywhere from consumer gadgets to industrial machinery. Then there are the specialists – parts meticulously engineered for demanding, niche applications. The HM05-1A83-150 high-voltage reed relay, from the renowned MEDER electronic brand (a division of Standex Electronics), firmly belongs to the latter category.

This isn’t your everyday switch. The HM05-1A83-150 is a powerhouse in miniature, designed to handle significant electrical stress with precision and reliability. If your work involves high-voltage systems, understanding this component is crucial.

What Makes the HM05-1A83-150 Stand Out?

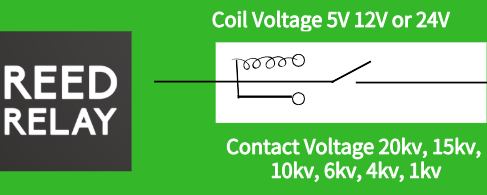

At its core, the HM05-1A83-150 is a 1 Form A (SPST-NO) reed relay, meaning it’s a single-pole, single-throw, normally-open switch. But its true distinction lies in its robust electrical characteristics:

- High Switching Voltage: It can switch voltages up to an impressive 7.5 kV, whether AC or DC.1 This is a critical capability for applications where high voltage isolation is paramount.

- Robust Breakdown Voltage: With a minimum breakdown voltage of 15 kVDC 2, it offers a substantial safety margin, ensuring dielectric integrity even under extreme conditions.

- Compact Power: Despite its high-voltage capabilities, it operates with a 5 VDC coil and can switch a maximum current of 3 A, handling up to 50 W of switched power.1

- Durable Construction: Encapsulated in epoxy, these relays are designed for through-hole mounting on PCBs, offering robust protection and various pin configurations.3

It’s worth noting that while the broader HM series can switch up to 10 kVDC, the HM05-1A83-150 specifically is rated for 7.5 kV.2 This highlights a golden rule in engineering: always consult the specific datasheet for the exact part number to avoid design miscalculations.

Where Does This High-Voltage Specialist Shine?

The HM05-1A83-150 isn’t built for general-purpose switching. Its design is tailored for environments where high voltage, precision, and safety are non-negotiable. Its primary applications include:

- High Voltage Test Sets: Essential for equipment that tests the dielectric strength and insulation of materials and components.3

- Cable Testers: Used in devices that verify the integrity and insulation quality of high-voltage cables.3

- Medical Equipment: Plays a critical role in various medical devices, such as RF surgery equipment, where high isolation and reliable switching are vital for patient safety.3

These applications underscore its importance in industries like Medical, Test and Measurement, and even Alternative Energy.4

Navigating the Procurement Landscape

Given its specialized nature, the HM05-1A83-150 isn’t typically a part you’ll find readily available for immediate online purchase. Distributors like TTI Asia list it as “Not Available Online,” directing buyers to contact sales representatives or request a quote.1 Other distributors, like Mobicon-Remote Electronic Pte Ltd, also require a quotation request.7

This means proactive sourcing is key. Expect potentially longer lead times and higher minimum order quantities compared to more common components. Direct engagement with sales teams from major distributors or specialized sourcing partners like Global Source Technology, Inc. 9 is often the most effective path. For definitive information on production status and authorized distributors, contacting Standex Electronics/MEDER electronic directly is always a wise step.

Maximizing Longevity: Best Practices for Reed Relays

Even the most robust components have their sensitivities. Reed relays, being mechanical devices, are susceptible to wear and tear if not applied correctly. Understanding common issues and implementing best practices can significantly extend their operational life:

- Cold Switching is King: This is perhaps the most impactful strategy. Design your system so that current or voltage is not applied to the switch until after the relay has fully closed and contact bounce has ceased. Similarly, remove the stimulus before the contacts open.10 This prevents damaging arcing and inrush currents, dramatically extending relay life.11

- Manage Reactive Loads: While reed relays perform best with purely resistive loads, if you must switch capacitive or inductive loads, be prepared. Capacitive loads can cause heavy inrush currents, leading to contact welding, while inductive loads generate damaging back-EMF upon opening.10 Since the HM05-1A83-150 doesn’t have a built-in coil suppression diode 1, external suppression (like a simple diode for DC loads or a snubber/varistor for AC loads) is essential to protect your driving circuitry.10

- Maintain Coil Overdrive: Ensure the coil voltage provides sufficient magnetic force to operate the contacts reliably. Aim for a coil voltage at least 25% higher than the “must operate by” voltage.11 Avoid driver ICs that reduce coil voltage after closure, as this can diminish overdrive and shorten life.11

- Thermal Management Matters: Temperature directly impacts coil resistance, which in turn affects the magnetic field strength. Keeping the operating temperature low helps maintain adequate overdrive and prevents sluggish operation.10

- Mind the Magnetic Field: Reed relays are sensitive to magnetic interference from adjacent components. Maintain adequate spacing (at least 5 mm on all sides) between relays on your PCB.12 For normally closed or latching relays, alternating their orientation can further minimize interaction.12

- Define “Failure” Proactively: In critical applications, even a “soft” failure – a temporary miss or stick – can be problematic.13 Some manufacturers define the first soft failure as the end-of-life criterion, allowing for proactive maintenance before a permanent “hard” failure occurs.13

The Bottom Line

The HM05-1A83-150 high-voltage reed relay is a specialized, high-performance component vital for demanding applications in medical, test, and measurement fields. While its procurement requires a more direct approach than off-the-shelf parts, its capabilities are indispensable where high voltage isolation and reliable switching are paramount. By adhering to best practices in electrical and mechanical design, engineers can unlock the full potential and ensure the long-term reliability of this unsung hero of high-voltage systems.