HM05-1A69-150 High-Voltage Reed Relay

I. Executive Summary

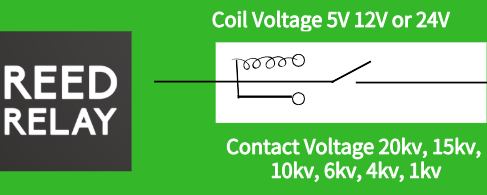

The HM05-1A69-150 is a specialized high-voltage reed relay, a product of Standex Electronics, frequently marketed under its MEDER electronic brand. This component is meticulously engineered for applications demanding exceptional high-voltage isolation and consistent switching performance. Its fundamental technical attributes include a 5 VDC coil, a 1 Form A (Single Pole Single Throw – Normally Open) contact configuration, and the capacity to manage substantial electrical loads. The relay is rated for switching voltages up to 10 kVAC or 10 kVDC and currents up to 3 Amperes, with a maximum switched power of 50 Watts. A critical safety and operational characteristic is its high breakdown voltage, specified at 15 kVDC.

The primary applications for the HM05-1A69-150 underscore its highly specialized nature. These include high-voltage test sets, precision cable testers, and advanced medical equipment, particularly those utilized in RF surgery. The consistent emphasis on “high voltage” across these critical applications indicates that the design and manufacturing approach for the HM05-1A69-150 inherently prioritizes robustness, insulation integrity, and long-term operational stability under electrical and environmental stress. This focus on reliability and safety, extending beyond mere performance metrics, profoundly influences material selection, mechanical design (such as leakage distances), and rigorous testing protocols. The very nature of its target applications dictates that this relay must perform flawlessly and predictably throughout its operational life, making its reliability a non-negotiable attribute.

The repeated identification of Standex Electronics, and its MEDER electronic brand, as the manufacturer, in conjunction with the specialized high-voltage application focus, points to a deliberate market strategy. This combination suggests that Standex/MEDER has cultivated a distinct position in the electronic components market by specializing in high-voltage switching solutions. This specialization implies that their research, development, and manufacturing processes are precisely tailored to address the unique engineering challenges inherent in high-voltage environments, such as managing arcing, ensuring robust dielectric strength, and minimizing parasitic effects. This deep expertise provides a significant competitive advantage, particularly in an industry increasingly moving towards solid-state alternatives, where achieving comparable galvanic isolation at such high voltages remains a substantial hurdle for many solid-state devices.

II. Introduction to the HM05-1A69-150 Reed Relay

Manufacturer and Product Series

The HM05-1A69-150 is a core component within the HM Series of reed relays, manufactured by Standex Electronics. It is important to recognize that “MEDER electronic” functions as a prominent brand under the umbrella of Standex Electronics, specifically for its reed switch-based solutions, thereby indicating a unified lineage for this product. Standex Electronics has established itself as a global leader in the design, development, and manufacturing of electro-magnetic components, with a particular strength in reed switch technology.

The dual branding, with “MEDER electronic” frequently appearing alongside Standex, suggests a strategic approach to market segmentation and brand recognition. “MEDER electronic” likely carries a strong legacy and a specialized reputation within the reed relay community, potentially representing a deeper, historical expertise in this specific technology. For technical professionals, understanding this relationship is vital for accurate component identification, effective sourcing, and appreciating the depth of engineering heritage behind the product. This indicates that the HM05-1A69-150 benefits from decades of specialized development in reed technology, contributing significantly to its high-performance characteristics.

General Description

Fundamentally, the HM05-1A69-150 is a high-voltage reed relay designed for PCB mounting, engineered to manage substantial electrical loads. A key design feature is its robust epoxy encapsulation, which provides superior protection for the delicate internal reed switch capsule. While the HM series generally offers various PCB pin configurations, the specific HM05-1A69-150 variant is distinguished by its axial cable option, facilitating direct high-voltage wiring, sometimes referred to as “sky wiring”.

Furthermore, the HM Series, including this relay, is positioned as a contemporary replacement for older mercury-wetted relays. This highlights its capability to deliver comparable or superior performance characteristics without the environmental and health hazards associated with mercury. This strategic positioning implies that the HM05-1A69-150 has been meticulously engineered to replicate or exceed the critical performance attributes of mercury-wetted relays, such as consistently low contact resistance, high reliability, and extended operational life, all without the use of hazardous materials. This necessitates the use of advanced contact materials, superior hermetic sealing, and precise manufacturing processes to achieve comparable stability and longevity. This design evolution reflects a broader industry movement towards more environmentally sustainable components, while simultaneously meeting stringent performance requirements, establishing the HM05-1A69-150 as a modern, compliant, and high-performance alternative.

III. Detailed Technical Specifications

The HM05-1A69-150 reed relay possesses a comprehensive set of electrical, timing, capacitance, environmental, and physical characteristics that define its operational capabilities and suitability for demanding applications.

Electrical Characteristics

The relay operates with a 5 VDC coil. Its nominal coil resistance is 30 Ohms, a value consistently supported by multiple datasheets. A minor deviation is noted in one source citing 33 Ohms, but the manufacturer’s detailed specifications confirm 30 Ohms for the 5V coil. The maximum DC coil current is specified at 0.167 Amperes, resulting in a coil power rating of 833 mW.

The relay features a 1 Form A (SPST-NO) contact configuration, indicating a Single Pole Single Throw, Normally Open arrangement. It is capable of switching a maximum current of 3 Amperes (DC or peak AC) and can handle switching voltages up to 10 kVAC or 10 kVDC. The maximum switched power is rated at 50 Watts.

The static contact resistance, measured at 0.5V and 50mA, has a maximum value of 150 mOhm. The insulation resistance is exceptionally high, typically 10^12 Ohm or, more precisely, 10^13 Ohm across contacts and between contact and coil. This high insulation resistance is fundamental for the relay’s target applications, ensuring minimal leakage currents that could compromise sensitive measurements or pose safety hazards in high-voltage test sets and medical equipment. The breakdown voltage is rated at 15 kVDC, with a dielectric strength between the coil and contacts also at 15 kVDC, conforming to EN 60255-5 standards. This robust isolation provides a substantial safety margin against transient overvoltages, preventing catastrophic arcing failures and ensuring long-term operational integrity. The standard part does not include a built-in coil suppression diode, implying that external suppression is typically required for proper operation and protection.

Timing Characteristics

The relay exhibits fast switching speeds. Its operate time, including contact bounce and measured with 100% overdrive, is 3.0 milliseconds. The release time, measured without coil suppression, is 1.5 milliseconds.

Capacitance

The typical capacitance across open contacts is very low, at 0.8 pF. While one general reference suggests an ideal of less than 0.5 pF for high-frequency signal integrity , 0.8 pF is still remarkably low for a high-voltage relay. This characteristic is critical for applications involving high-frequency signals or sensitive low-voltage measurements, as it minimizes signal distortion, insertion loss, and crosstalk. In test and measurement equipment, where signal fidelity is paramount, this low capacitance ensures that the relay does not degrade the integrity of the signal being switched. The typical capacitance between the contact and coil is 5.0 pF.

Environmental Data

The HM05-1A69-150 is designed to operate within an ambient temperature range of -20 to 70 °C. For storage, the relay can withstand temperatures from -35 to 105 °C. It is capable of enduring a maximum soldering temperature of 260 °C for a 5-second dwell time. The relay demonstrates high mechanical robustness, with a shock resistance of 50 g (for a 1/2 sine wave duration of 11 ms) and a vibration resistance of 20 g (from 10 – 2000 Hz). Its fully sealed construction indicates resistance to washing processes.

Ожидаемая продолжительность жизни

Under light load conditions (switching 5 V – 10 mA, DC only, and less than 10 pF stray capacitance), the HM05-1A69-150 has a life expectancy of 50 x 10^6 (50 million) cycles. Reed relays generally are recognized for their extended lifespans, capable of billions of switching operations under low-level signal conditions without significant wear, often surpassing the lifespan of traditional electromechanical relays.

Physical Characteristics and Mounting

The relay’s body dimensions are 68 mm in length, 19 mm in breadth, and 19.8 mm in height. A critical distinction for the HM05-1A69-150 is its termination style: it features

Axial Cables (specifically AWG20 Silicone high-voltage wire, UL-Style 3239, with tinned ends) designed for direct wiring. While some general series information may refer to “Through Hole” mounting , the “150” suffix in the part number definitively indicates the axial cable configuration.

This “150” suffix is not merely a part number variant but signifies a fundamental design choice tailored for extreme high-voltage applications. By providing pre-attached high-voltage axial cables, the manufacturer directly addresses a significant challenge in high-voltage circuit design: maintaining sufficient creepage and clearance distances on a Printed Circuit Board (PCB) to prevent arcing and leakage. This design feature simplifies high-voltage routing for engineers, reduces the risk of field failures due to improper PCB layout, and enhances overall system safety and reliability. This directly supports its use in applications like cable testers and medical equipment, where high-integrity high-voltage connections are paramount.

The relay is a sealed unit offering high voltage isolation through its epoxy encapsulation. Its housing material is polycarbonate, and the sealing compound is polyurethane. These material choices are deliberate and crucial for the relay’s high-voltage performance and longevity. Epoxy and polyurethane are selected for their superior dielectric properties, mechanical stability, and resistance to environmental factors such as moisture and contaminants. The principle of using a “soft inner material” for encapsulation, as advocated by some manufacturers to cushion the reed switch capsule and prevent stress , suggests that Standex/MEDER likely employs a similar technique. This minimizes mechanical stress on the delicate glass reed switch capsule, preventing micro-cracks or internal stresses that could lead to contact resistance instability or premature failure over time, directly contributing to the HM05-1A69-150’s impressive life expectancy and reliability in demanding environments. The relay also incorporates a magnetic shield.

The exceptionally high insulation resistance (10^13 Ohms) and breakdown voltage (15 kVDC) are standout specifications. These high isolation values are not just impressive figures; they are fundamental requirements for the HM05-1A69-150’s target applications. In high-voltage test sets, high insulation resistance ensures that leakage currents do not interfere with sensitive measurements or pose safety hazards. In medical equipment, robust isolation is paramount for patient and operator safety, preventing dangerous current paths. The high breakdown voltage provides a substantial safety margin against transient overvoltages and ensures long-term operational integrity, preventing catastrophic arcing failures. This characteristic directly addresses the core need for high-voltage handling capabilities and robust isolation in critical applications.

Table 1: HM05-1A69-150 Detailed Technical Specifications

| Characteristic | Value | Unit | Source(s) |

| Electrical | |||

| Напряжение катушки | 5 В постоянного тока | VDC | |

| Сопротивление катушки | 30 | Ohms | |

| Coil Current (DC) Max | 0.167 | A | |

| Coil Power | 833 | mW | |

| Relay Contact Form | 1 Form A (SPST-NO) | ||

| Max Switched Current | 3.0 | A | |

| Напряжение переключения | 10 kVAC, 10 kVDC | kV | |

| Max Switched Power | 50 | W | |

| Static Contact Resistance (max) | 150 | mOhm | |

| Insulation Resistance (typ.) | 10^13 (Across contacts, Contact to coil) | Ohm | |

| Breakdown Voltage | 15 | kVDC | |

| Катушка/контакт диэлектрической прочности | 15 | kVDC | |

| Coil Suppression Diode | No (External required) | ||

| Timing | |||

| Operate Time incl. Bounce | 3.0 | ms | |

| Release Time | 1.5 | ms | |

| Capacitance | |||

| Across Open Switch (typ.) | 0.8 | pF | |

| Contact to Coil (typ.) | 5.0 | pF | |

| Environmental | |||

| Рабочая Температура | -20 to 70 | °C | |

| Температура хранения | -35 to 105 | °C | |

| Soldering Temperature (max.) | 260 (5 sec. dwell) | °C | |

| Shock Resistance | 50 | g | |

| Vibration Resistance | 20 | g | |

| Washability | Fully sealed | ||

| Ожидаемая продолжительность жизни | |||

| Switching Life (5V-10mA DC) | 50 x 10^6 | Cycles | |

| Physical | |||

| Body Length | 68 | mm | |

| Body Breadth | 19 | mm | |

| Body Height | 19.8 | mm | |

| Стиль завершения | Axial Cables (AWG20 Silicone HV wire) | ||

| Key Features | Sealed, High Voltage Isolation, Epoxy Encapsulated, Magnetic Shield | ||

| Housing Material | Polycarbonate | ||

| Sealing Compound | Polyurethane |

IV. Availability and Sourcing Information

Current Stock Status and Lead Times

The HM05-1A69-150 is frequently reported as “0 In Stock” or “Not Available Online” by major distributors such as TTI Asia and Mouser. For Mouser, the component is specifically listed as

non-stocked, with an estimated factory lead-time of 10 weeks. Procurement from Mouser requires a

minimum order quantity (MOQ) of 20 units, and subsequent orders must be placed in multiples of 20.

In contrast, Okmarts claims the “MEDER Relay HM05-1A69-150” is “Order in stock” and offers “Free shipping… and ship within 1-5 days”. This presents a notable contradiction in immediate availability. Other distributors, including Mobicon-Remote Electronic Pte Ltd and Jotrin Electronics , explicitly state that pricing and availability information require a direct quotation request. Further underscoring potential supply chain challenges for high-voltage reed relays, Farnell France indicates that a similar part, HE05-1A83-150 (from the related HE series by Standex/MEDER), is “no longer stocked”.

This consistent reporting of “0 In Stock” or “Not Available Online” from major, authorized distributors, coupled with a substantial 10-week factory lead time, is a critical signal. The “no longer stocked” status for a similar high-voltage part from Farnell reinforces a broader trend. This pattern strongly suggests that the HM05-1A69-150 is not a high-volume, readily available commodity component. Its specialized nature, catering to niche high-voltage applications, likely means it is produced in smaller batches or on a build-to-order basis. For project managers and procurement teams, this translates into a critical need for proactive and strategic sourcing. Relying on immediate availability is not feasible; instead, early engagement with sales representatives, direct quotation requests, and robust lead-time planning are essential to avoid project delays. This highlights the inherent trade-off between the high technical performance of specialized components and their often-complex supply chain dynamics.

Pricing Details

Mouser provides a tiered pricing structure for the HM05-1A69-150, with prices decreasing at higher quantities: $44.19 per unit for 20 units, and $36.39 per unit for 200 units. Okmarts, however, lists a significantly higher unit price of USD $165.38.

The stark contrast between Mouser’s “non-stocked, 10-week lead time, tiered pricing” and Okmarts’ “in stock, 1-5 day shipping, single high price” is a significant contradiction. This discrepancy can stem from several factors. Okmarts might operate as an independent or grey market reseller, potentially having acquired excess inventory, which allows for immediate stock but often at a premium price. Authorized distributors, such as Mouser and TTI, typically adhere to manufacturer-set pricing and lead times for new production. Even large distributors can experience slight lags in real-time global inventory updates for highly specialized or lower-volume parts. For technical professionals, this implies a crucial due diligence step: always verify stock and pricing directly with multiple authorized distributors. While a quick “in stock” claim might be tempting, the significantly higher price and the contradiction with major channels warrant caution. Relying on unauthorized sources without proper verification could lead to higher costs, lack of technical support, or even counterfeit components. This underscores the importance of strong relationships with established distribution partners for critical components.

Key Distributors

Authorized distributors for Standex Electronics (and its MEDER electronic brand) include a wide network:

- Mouser Electronics

- TTI, Inc.

- DigiKey Electronics

- Mobicon-Remote Electronic Pte Ltd

- Jotrin Electronics

- Global Source Technology, Inc.

- Supreme Components International

- Heilind

- Master Electronics

- Transfer Multisort Elektronik (TME)

Table 2: HM05-1A69-150 Availability and Pricing Overview

| Distributor Name | Stock Status | Estimated Lead Time | Minimum Order Quantity (MOQ) | Unit Price (USD) | Notes |

| Mouser Electronics | Non-Stocked | 10 Weeks | 20 units (multiples of 20) | $44.19 @ 20 units, $36.39 @ 200 units | Authorized distributor; requires advance planning. |

| TTI Asia | 0 In Stock / Not Available Online | Not specified | Not specified | $44.19 @ 20 units, $36.39 @ 200 units | Authorized distributor; contact sales for current information. |

| Okmarts | In Stock | 1-5 Days | Not specified | $165.38 | Claims in-stock; significant price discrepancy compared to others. |

| Mobicon-Remote Electronic Pte Ltd | Contact for Quote | To be Quoted | To be Quoted | To be Quoted | Requires direct quotation request. |

| Jotrin Electronics | Contact for Quote | To be Quoted | To be Quoted | To be Quoted | Requires direct quotation request. |

| Farnell France (similar part HE05-1A83-150) | No Longer Stocked | N/A | N/A | N/A | Indicates potential broader supply chain challenges for similar HV reed relays. |

导出到 Google 表格

V. Common Operational Challenges and Failure Modes

Understanding the potential operational challenges and failure modes of reed relays, particularly high-voltage variants like the HM05-1A69-150, is crucial for ensuring long-term reliability and system integrity.

Impact of High Current/Power Inrushes

High current or high power inrushes are consistently identified as the most damaging and frequent cause of contact damage in reed relays. The power rating of a relay is defined as the product of the voltage across the open contacts immediately before closure and the instantaneous current at the moment they first make contact.

Capacitive loads are particularly problematic in this regard. While charging capacitive loads can generate significant inrushes, discharging capacitors pose an even greater issue. In such scenarios, the current is often limited only by the inherent resistance of the reed switch and the PC board traces. Even capacitors charged to relatively low voltages can produce current inrushes reaching tens of amperes. Although these transients may last only microseconds, they are sufficient to cause damage to small reed switches. The energy stored in a capacitance is proportional to ½ CV², meaning that the energy, and thus the potential for damage, increases quadratically with voltage. This phenomenon becomes a critical concern when discharging cables after high-voltage proof testing, where stored energy can be immense.

The physical damage to contacts manifests in several ways. A severe current overload can lead to rapid melting of the contact area, causing the two surfaces to fuse together and form a “hard weld” immediately upon contact closure. Less severe current inrushes may result in a milder weld or a gradual accumulation of material, forming a “pip” on one contact, accompanied by erosion, creating a “crater” on the opposing contact. The direction of material transfer depends on the direction of current flow. Over time, these formations can interlock, leading to mechanical sticking of the contacts.

This establishes a direct and severe cause-and-effect chain: uncontrolled transient currents, particularly inrush from capacitive loads or arcing from inductive loads, directly lead to physical degradation of the relay contacts. This physical damage is the root cause of subsequent electrical failures, such as contacts sticking or failing to make. For designers, merely adhering to the relay’s specified maximum steady-state current, voltage, or power ratings is fundamentally insufficient. A comprehensive understanding of the dynamic behavior of the load, especially its transient characteristics (e.g., peak inrush currents, magnitudes of back electromotive forces), is paramount. Failure to account for these transient stresses will inevitably lead to premature relay failure, regardless of the relay’s nominal ratings. This necessitates detailed load analysis and, frequently, the implementation of external protection circuitry, such as diodes, snubbers, or varistors, to ensure the relay operates within its true safe operating area. This is particularly critical in high-voltage applications, where the energy stored in reactive components can be immense and highly destructive.

Effects of Reactive Loads

Reed relays demonstrate optimal reliability when switching purely resistive loads. As previously detailed, capacitive circuits introduce heavy inrush currents that can lead to premature contact failure or contact welding. Inductive loads are prone to causing excessive arcing when contacts open. To mitigate this, back EMFs generated by inductive loads must always be limited, typically by incorporating a simple diode for DC loads or a Snubber or Varistor network for AC loads.

Magnetic Interaction with Adjacent Relays

When reed relays are densely packed or stacked closely together, the magnetic field generated by an adjacent relay can partially oppose the magnetic field of the relay alongside it. This phenomenon reduces the relay’s effective sensitivity. Consequently, a higher coil voltage becomes necessary to reliably operate the affected relay. For very small relays, this required increase in coil voltage can be as high as 40%, potentially rendering the relay inoperable at its nominal coil voltage. Normally closed (Form B) and latching reed relays, which incorporate permanent magnets, exert a greater magnetic influence on adjacent relays, necessitating careful layout considerations.

Temperature Effects on Coil Resistance and Operation

The coil resistance of a reed relay is temperature-dependent, increasing by 0.39% for every degree Celsius rise in temperature. Assuming a constant voltage coil supply, a mere 30°C increase in temperature can lead to a 12% increase in coil resistance, resulting in a corresponding 14% reduction in the power delivered to the coil. This reduction in coil power directly diminishes the magnetic overdrive, which can significantly reduce the relay’s operational life. Crucially, at elevated temperatures, the relay may fail to operate reliably at its specified nominal coil drive voltage. It is important to consider the internal operating temperature of the relay, which is the sum of the ambient temperature and any self-heating generated by high carry current flowing through the switch resistance (I²R Watts). For relays operating at ambient temperatures significantly above 20°C, the pull-in voltage and maximum coil voltage must be recalculated using specific temperature compensation factors.

Relay reliability is not a monolithic characteristic but a dynamic outcome influenced by the cumulative effect of various stresses. This is evident in how temperature increases coil resistance, thereby reducing overdrive. Similarly, magnetic interference from adjacent relays also reduces the effective coil field, impacting sensitivity. Both of these phenomena lead to insufficient magnetic drive, which directly contributes to reduced operational life and potential “miss” failures. Furthermore, self-heating from the relay’s own carry current (I²R Watts) further compounds the thermal stress. This illustrates a complex, interconnected web of causal relationships where ambient temperature or internal self-heating leads to increased coil resistance, which in turn reduces the effective coil drive or overdrive, ultimately decreasing reliability and life expectancy. Similarly, close proximity or suboptimal layout results in magnetic interference, which also reduces the effective coil drive, leading to decreased reliability and life expectancy. Optimal performance and longevity require a holistic design approach that systematically addresses each contributing factor. This includes meticulous thermal management (e.g., ensuring adequate cooling, considering internal self-heating), intelligent physical layout (e.g., maintaining sufficient spacing, utilizing magnetic shielding), and ensuring that the coil drive voltage consistently provides adequate overdrive under all anticipated operating and environmental conditions. This integrated approach is particularly vital in high-density PCB designs where thermal and magnetic coupling effects are amplified.

Defining and Classifying Relay Failures

Reed switches or relays ultimately fail in one of three primary modes:

- Sticking: The relay fails to open when the coil is de-energized, meaning its contact resistance remains below a defined threshold when it should be open.

- Missing: The relay fails to close when the coil is energized, indicating its contact resistance remains above a defined threshold when it should be closed.

- Static Contact Resistance Drift: The static contact resistance gradually increases over time to an unacceptable level, even if the contacts are physically making.

Failures are further categorized as “soft” or “hard.” A soft failure is a transient issue where a switch misses or sticks for a few milliseconds after coil activation or de-activation, but then recovers from the problem shortly thereafter (typically within half a second). A

hard failure, conversely, is a permanent failure where the switch does not recover from the initial soft failure by the time a subsequent check is performed. For critical applications such as Automated Test Equipment (ATE), Coto, a prominent relay manufacturer, adopts a deliberately conservative criterion for “expected life” estimation. They define failure as the

first occurrence of a soft failure due to sticking, missing, or excessive contact resistance, recognizing that even a single soft failure can be highly problematic in such applications. This detailed classification of failures, coupled with the conservative definition of “expected life” by manufacturers like Coto, underscores a critical nuance in safety-critical applications. In fields like ATE and medical equipment, even momentary glitches or transient failures are often unacceptable because they can lead to erroneous measurements, compromised safety, or significant operational disruptions. This approach to defining failure implies that the design and testing of components like the HM05-1A69-150 must prioritize absolute predictability and flawless operation, rather than merely meeting average lifespan metrics. It compels engineers to design systems with robust error detection and handling, acknowledging that even a fleeting anomaly can have severe consequences.

Reliability Testing and Life Estimation Considerations

Understanding the number of switching cycles a relay can endure under various electrical load conditions is a critical factor in selecting the appropriate reed relay for an application. Under very light loads, reed relays can achieve billions of closure cycles before failure. Life tests can be concluded once a certain proportion of relays (typically at least 50%) have failed, rather than testing all units to failure. Once Weibull regression parameters are determined from life test data, the fitted equation can be used to predict key reliability metrics such as Mean Cycles Before Failure (MCBF), expected life before 1% part failure, and characteristics related to infant mortality and wearout. It is important to note that direct comparison of reliability data published by different relay manufacturers can be challenging due to variations in their failure criteria or statistical presentation methods.

VI. Best Practices for Application and Longevity

To maximize the performance, reliability, and lifespan of the HM05-1A69-150 high-voltage reed relay, adherence to specific application best practices is essential. These practices address the common operational challenges and failure modes previously discussed.

Load Management and Protection

Cold Switching: This technique significantly extends relay life. It involves designing the system such that the current or voltage stimulus is not applied to the switch until after the relay has operated and contact bounce has finished. Similarly, the stimulus is removed before the contact is opened. This prevents arcing and contact degradation during the make and break cycles.

Avoiding Reactive Loads: Reed relays are most reliable when switching purely resistive loads. For applications involving inductive or capacitive loads, external protection is imperative. For inductive loads, back EMFs should always be limited, typically by incorporating a simple diode for DC loads or a Snubber or Varistor network for AC loads.

Managing Inrush Currents: A thorough understanding and limitation of inrush currents are crucial, particularly with capacitive loads. The energy stored in a capacitance increases quadratically with voltage, making high-voltage capacitive discharges extremely damaging. Proper design should aim to prevent or significantly limit these inrushes to prevent contact damage.

Coil Drive and Overdrive Optimization

Maintain High Coil Voltage: To achieve maximum life from the normally-open contact, it is advisable to provide the highest possible magnetic field. This is most directly achieved by maintaining a high coil current, using the highest coil voltage permissible within the relay’s specified limits.

Adequate Overdrive: A relay with a nominal coil voltage of 5V, like the HM05-1A69-150, typically has a “must operate by” voltage of around 3.8V. To guarantee at least 25% overdrive for all relays, the voltage applied to the coil should be maintained at least 25% higher than this “must operate by” voltage, i.e., at least 4.75V.

Avoid Lowering Coil Voltage After Closure: It is not recommended to use relay driver ICs that allow the coil voltage to be lowered after the relay closes to save power. Most small reed relays do not possess sufficient differential between their pull-in and drop-out voltages to maintain adequate overdrive under such conditions, which can negatively impact relay life.

Independent Power Supply: Relay coils are inductive and can generate potentially damaging spikes on power lines. It is considered good design practice to provide an independent power supply unit (PSU) specifically for the relay coils. For relays without built-in kickback suppression diodes, external diode inductive spike suppression should be considered.

Thermal Management

Keep Operating Temperature Low: The coil resistance of a reed relay increases by 0.39% for every degree Celsius rise in temperature. This increase reduces the power supplied to the coil, diminishing overdrive and potentially shortening relay life. Therefore, keeping the operating temperature as low as possible is beneficial.

Allow for Self-Heating: If the relay carries a high current, internal self-heating (due to I²R losses in the switch resistance) will occur. In such cases, it is necessary to account for this and allow a little more time before turning on the current through the switch to ensure stable operation.

Physical Layout and Magnetic Shielding

Maintain Spacing: When mounting reed relays, especially in close proximity, board layout considerations are necessary. A “rule of thumb” spacing of at least 5 mm on all sides between reed relays is recommended to minimize magnetic interaction. For normally closed and latching reed relays, which contain permanent magnets, the magnetic effect on adjacent relays is greater, and alternating their orientation end-to-end is advisable.

Use Ferrous Metal Shells: If available, selecting a relay with a ferrous metal shell can help minimize magnetic interaction and maintain maximum overdrive. Internal magnetic shielding, a feature in Standex/MEDER reed relays, also prevents magnetic coupling between closely stacked relays, which is essential for functional PCB testing in high-density applications.

These best practices collectively illustrate a proactive approach to designing for reliability, shifting from merely reacting to failures to anticipating and mitigating potential failure mechanisms from the outset. This is particularly crucial for high-voltage and high-reliability applications where the consequences of failure can be severe. The consistent message across these recommendations is the fundamental interplay of electrical, thermal, and magnetic factors. Each of these elements independently influences relay performance and longevity, but their combined effects can be synergistic. For instance, increased temperature reduces effective coil drive, and magnetic interference does the same. Both contribute to insufficient overdrive, which can lead to contact issues. Therefore, optimal performance and longevity require a holistic design approach where all these factors are managed in an integrated manner. This includes meticulous thermal management, intelligent physical layout, and ensuring that the coil drive voltage consistently provides adequate overdrive under all anticipated operating and environmental conditions.

VII. Typical Applications and Markets

The HM05-1A69-150 high-voltage reed relay is specifically designed for environments demanding robust high-voltage switching and isolation capabilities. Its characteristics make it highly suitable for specialized applications and markets.

Primary Applications

The core applications for the HM05-1A69-150 are:

- High Voltage Test Sets: These systems require precise and reliable switching of high voltages for testing insulation, breakdown, and other electrical properties of components and assemblies.

- Cable Testers: Similar to high-voltage test sets, cable testers utilize the relay’s high voltage handling to verify the integrity and insulation of various types of cables, often after high-voltage proof testing where significant capacitive energy needs to be managed.

- Medical Equipment (e.g., RF Surgery): In medical devices, particularly those involving high-frequency or high-voltage energy delivery like RF surgery equipment, the relay provides critical isolation and switching functions, ensuring patient and operator safety and precise energy control.

Primary Markets

The primary markets served by these relays align directly with their specialized applications:

- Medical: This market demands components with exceptional reliability, safety, and long-term stability due to the direct impact on human health.

- Тестирование и измерение: This sector requires high precision, signal integrity, and robust components that can withstand repetitive, often demanding, test cycles.

Broader Applications within HM Series

While the HM05-1A69-150 is tailored for the aforementioned high-voltage applications, the broader HM Series of reed relays from Standex Electronics finds use in a wider array of industries, including:

- Alternative Energy

- Appliance

- Automotive

- Бытовая электроника

- HVAC

- Industrial

- Military & Aerospace

The demanding nature of these target applications (medical, test & measurement) necessitates extreme precision, safety, and long-term reliability. This directly influences the relay’s design and performance requirements, leading to the robust specifications observed. Furthermore, while the HM series as a whole is versatile, the HM05-1A69-150, with its specific axial cable termination and 10kV switching capability, is particularly tailored for the most demanding high-voltage scenarios. This distinguishes it from other HM series variants and highlights its specialized role in applications where maintaining high-integrity high-voltage connections is paramount.

VIII. Conclusions

The HM05-1A69-150 is a highly specialized, high-performance reed relay from Standex Electronics, marketed under its MEDER electronic brand, designed for critical high-voltage switching and isolation. Its robust electrical characteristics, including a 5VDC coil, 1 Form A (SPST-NO) contacts, 3A switching current, 10kVAC/DC switching voltage, 50W switched power, and an impressive 15kVDC breakdown voltage, position it as a reliable solution for demanding environments. The exceptionally high insulation resistance (10^13 Ohms) and low capacitance (0.8 pF across open contacts) are fundamental to its suitability for applications requiring uncompromising isolation and signal integrity, particularly in medical and test & measurement equipment.

A significant design feature of the HM05-1A69-150 is its axial cable termination, which directly addresses the challenges of maintaining adequate creepage and clearance distances in high-voltage circuit design, enhancing overall system safety and reliability. The use of epoxy encapsulation, polycarbonate housing, and polyurethane sealing compound further contributes to its durability and long operational life, making it a modern, environmentally responsible replacement for mercury-wetted relays.

However, procurement of the HM05-1A69-150 may present supply chain challenges, as it is frequently non-stocked by major distributors with significant factory lead times. This necessitates proactive and strategic sourcing to avoid project delays. Discrepancies in reported availability and pricing across different vendors underscore the importance of thorough due diligence and direct engagement with authorized distributors.

Operational longevity and reliability are highly dependent on careful application. The relay is susceptible to damage from high current/power inrushes, especially from reactive (capacitive and inductive) loads, which can lead to contact welding or degradation. External protection circuitry (diodes, snubbers/varistors) is often required. Furthermore, magnetic interaction from closely spaced relays and elevated operating temperatures can reduce effective coil overdrive, impacting performance and lifespan.

To maximize the HM05-1A69-150’s reliability and lifespan, it is recommended that engineers implement best practices such as cold switching, maintaining optimal coil overdrive, ensuring adequate thermal management, and adhering to recommended physical spacing and magnetic shielding guidelines. A comprehensive understanding of the dynamic load characteristics and a holistic design approach that considers electrical, thermal, and magnetic factors are paramount. By adhering to these principles, the HM05-1A69-150 can deliver its intended high-reliability performance in critical high-voltage applications.