High-Performance Reed Relays: Modules & Matrices for Precision Switching

In the dynamic world of electronics, components that offer unparalleled precision, robust isolation, and rapid switching are highly sought after. Among these, reed relays stand out as a fundamental and indispensable technology. This article delves into the core of high-performance reed relay modules and the sophisticated architecture of advanced reed relay matrices, highlighting why they are the go-to solution for applications demanding superior signal integrity, high voltage handling, and exceptional operational speed.

Understanding High-Performance Reed Relay Modules

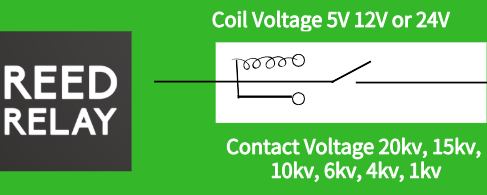

At its essence, a reed relay functions as an electromechanical switch, meticulously engineered for reliability and precision. Its fundamental structure comprises a reed switch, an electromagnetic coil, and associated blades, all hermetically sealed within a glass enclosure filled with a dry inert gas. This encapsulation is crucial, protecting the contacts from oxidation, corrosion, and contaminants, ensuring consistent performance and an incredibly long life.

Key Features and Design Excellence

The HRM Series of high-voltage reed relay modules exemplifies modern design excellence. These modules are designed for seamless integration into demanding environments, offering:

- Exceptional High Voltage Capability: Many models boast a dielectric strength up to 15 KVDC between contacts and 10-15 KVDC from contact to coil, providing critical safety and isolation.

- DIN Guide Mounting: A standardized feature for quick, secure, and organized installation in industrial control cabinets.

- LED Indicators: Integrated lights provide immediate visual feedback on operational status, simplifying monitoring and troubleshooting.

- Professional Circuit Protection: Essential safeguards for both the relay and interconnected systems.

- RoHS Compliance: Adherence to stringent environmental standards by restricting hazardous substances.

- Custom Design Options: Tailored solutions to meet unique application requirements.

These modules are known for their fast response times and low contact resistance, making them ideal for applications requiring high switching speeds and minimal signal distortion. Their robust construction ensures durability, with a life expectancy often rated at 5 x 107 operations under specified load conditions.

Performance Data Overview

Understanding the electrical and mechanical performance parameters is crucial for accurate component selection. The HRM Series offers a wide range of specifications to suit diverse needs:

| Relay Model | Contact Rating (W) | Max. Switching Voltage (V) | Max. Switching Current (A) | Max. Carry Current (A) | Contact Resistance (MΩ) | Dielectric Strength (Between contact VDC) | Dielectric Strength (Contact to coil VDC) | Insulation Resistance (Ω) | Operate Time (ms) | Release Time (ms) | Life Expectancy (Ops) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HRM-1A10 | 10 | 10000 | 3.5 | 5.0 | 150 | 15000 | 10000 | 10^12 | 3.0 | 1.5 | 5X10^7 (500VDC-100mA) |

| HRM-1A15 | 10 | 7000 | 3.5 | 5.0 | 150 | 15000 | 10000 | 10^12 | 3.0 | 1.5 | 5X10^7 (500VDC-100mA) |

| HRM-2A10 | 10 | 10000 | 3.5 | 5.0 | 150 | 15000 | 10000 | 10^12 | 3.0 | 1.5 | 5X10^7 (500VDC-100mA) |

| HRM-2C01 | 10 | 240 | 4.0 | 4.0 | 200 | 1000 | 10000 | 10^9 | 4.5 | 3.7 | 5X10^7 (500VDC-100mA) |

| HRM-6A06 | 100 | 1000 | 1.0 | 2.5 | 300 | 6000 | 6000 | 10^11 | 1.0 | 0.1 | 5X10^7 (500VDC-10mA) |

| HRM-12A15 | 50 | 10000 | 3.0 | 5.0 | 150 | 15000 | 15000 | 10^11 | 3.5 | 2.0 | 5X10^7 (500VDC-100mA) |

| HRM-20A04 | 100 | 1000 | 1.0 | 2.5 | 150 | 4000 | 4000 | 10^11 | 1.0 | 0.1 | 5X10^7 (500VDC-100mA) |

The Power of Reed Relay Matrices

Building upon individual reed relays, a reed relay matrix involves arranging multiple relays into a sophisticated network. This configuration enables complex signal routing and intricate switching patterns, making these matrices vital for applications demanding multi-channel control and high-density switching solutions.

Advantages of Reed Relay Matrices

Reed relay matrices offer distinct advantages over other switching technologies:

- High-Density Integration: Their small size allows for high packing density, crucial for compact electronic systems and high-density PCB mounting.

- Superior Signal Integrity: With extremely low contact resistance (typically less than 50 milliohms) and exceptionally high insulation resistance (often exceeding 1015 ohms), they ensure negligible signal loss and precise measurements, even for femtoamps and nanovolts.

- Excellent RF Performance: Many reed relays are designed for high-frequency applications, offering RF performance up to 7 GHz, making them suitable for telecommunications and wireless markets.

- Robustness: The hermetically sealed design provides outstanding environmental robustness, capable of withstanding shocks up to 200 Gs and significant vibrations.

- Customization and Versatility: Available in various package styles, multi-pole configurations (up to 20 channels in the HRM series), and multiple contact forms (Form A, B, C, D, E).

Design Considerations for Matrices

Designing with reed relay matrices requires careful attention to magnetic interactions. When relays are placed in close proximity, magnetic coupling can occur, potentially affecting sensitivity. To mitigate this, specialized magnetic shielding, often using Mu-metal, is employed. This concentrates the magnetic field, enhancing efficiency and reliability, and crucially, permits side-by-side stacking without significant performance degradation.

Diverse Applications of Reed Relay Technology

The unique combination of high voltage isolation, exceptional signal integrity, and rapid switching capabilities makes reed relay modules and matrices indispensable across a wide array of demanding industries and critical applications:

- Automated Test Equipment (ATE): Widely adopted for their high-density board integration, excellent RF performance, and consistent, reliable switching with extended lifetimes and low contact resistance. Ideal for complex test sequences and precise signal routing.

- Lääketieteelliset laitteet: Employed in critical devices like defibrillators, electroconvulsive therapy (ECT) devices, and laser systems, where reliability and high isolation are paramount for patient safety.

- Automotive Electronics: Increasingly used in electric vehicle (EV) charging systems for switching high voltage power to batteries, as well as in ignition and lighting systems.

- Aerospace and Defense: Relied upon for critical applications involving high voltage signal switching in radar systems, electronic warfare, and missile guidance, where unwavering reliability under extreme conditions is essential.

- Telecommunications and RF Switching: Utilized for high-frequency applications such as photomultipliers and antenna tuners, where signal integrity and performance at high frequencies are crucial. Their compact design supports high-density assembly.

- Power Switching and Distribution: Used for safely switching high voltage outputs in power supplies and efficiently routing high voltage signals within complex power distribution networks.

- Battery Management Systems (BMS): Specifically designed for demanding applications like isolation measurement due to their low leakage currents and high isolation properties.

- Industrial Controls and Instrumentation: Essential for precise control and measurement in various industrial settings.

Conclusion: The Indispensable Role of Reed Relays

From miniature and subminiature packages to robust high-voltage capabilities, reed relay technology continues to be a cornerstone in modern electronics. The versatility of reed relay modules, with their diverse channel configurations and contact forms, combined with the sophisticated capabilities of reed relay matrices for high-density switching and complex signal routing, underscores their critical importance.

Their inherent reliability, stemming from hermetically sealed contacts and exceptional electrical characteristics, ensures consistent and predictable performance in the most demanding applications. As electronic systems become increasingly compact, complex, and demanding in terms of performance and reliability, the distinct attributes of reed relay technology will continue to secure its indispensable role in precision switching and critical isolation functions across industries like ATE, medical, automotive, and telecommunications.

For more detailed specifications or to discuss custom solutions for your specific application, please contact our experts.